1. SCM Objectives

Firstly, the objectives of SCM are to meet or exceed the required or demanded customer service level in targeted markets/segments and to optimise total supply chain investment and cost. This service/cost approach has long been regarded as central to supply chain management. This approach requires companies to have a clear understanding of both issues. Customer service requirements, dictated by the market place, “sets the spec” for the supply chain. Achieving this level of service at the optimal cost focuses attention on the elimination of “non value adding activities” (NVAs) throughout the supply chain.

2. SCM Philosophy

Secondly, every product or service is delivered to the final consumer (the only source of “real” money in the chain) through a series of often complex movements between companies which comprise the complete chain. An inefficiency anywhere in the chain will result in the chain as a whole failing to achieve its true competitive potential. In other words, supply chains are increasingly competing with other supply chains rather than, in the more traditional axiom, companies simply competing with other companies. The phrase “supply chain” is used to indicate that the chain is only as strong as its weakest link.

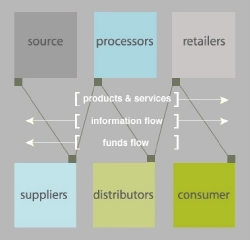

The representation in Figure 1 (below) of a “macro” supply chain shows materials flowing from the raw material source through the various stages in the chain to the final consumer. Money then flows back down the chain. The point is that every link matters and that value is added, and profit generated, at each link along the way.

Figure 1 - The External Supply Chain

Most businesses can be described in terms of the five functions: buy; make; store; move; and, sell. This is known as the “micro” or internal supply chain as shown in Figure 2.

Figure 2 - The Internal Supply Chain

Traditionally these functions have been managed in isolation, often working at cross purposes. SCM means thinking beyond the established boundaries, strengthening the linkages between the functions, and finding ways for them to pull together. A recognition that the whole is greater than the sum of the parts calls for more effective integration between purchasing and procurement (buy), production planning and control (make), warehouse management (store), transport management (move) and customer relationship management (sell), as illustrated in Figure 3.

Figure 3 - Integrating the Internal Supply Chain

3. Managing the Flows

For a supply chain to achieve its maximum level of effectiveness and efficiency, material flows, money flows and information flows throughout the entire chain must be managed in an integrated and holistic manner, driven by the overall service and cost objectives. The view of a macro chain shown in Figure 1 (above) indicates the way in which material, money (funds) and information flow between the companies which participate in the chain. Similar logic can be applied to the functions which comprise the micro chain. It can be argued that managing the information flows is the most critical of these activities. This is because the flow or movement of materials or money is usually triggered by an associated information movement. Effective management of material and financial flows is, therefore, predicated upon the effective management of the related information flows. For this reason, information and communications technology (ICT) is becoming an increasingly important SCM enabler.

4. Supply Chain Relationships

Finally, this holistic approach requires a reappraisal of the way in which both internal and external customer/supplier relationships are created and managed. SCM is not a “zero-sum” game based on adversarial relationships. Rather, it needs to be a “win-win” game based on partnership approaches. This point is relevant to the interactions between the key “internal” supply chain functions of buy, make, store, move and sell, as well as to relationships between an organisation and its external customers and suppliers. One of the biggest manifestations of the application of supply chain philosophy in recent years has involved the move away from adversarial relationships with key external suppliers towards relationships which are based on mutual trust and benefits, openness and shared goals and objectives.

Source: Sweeney, E. (ed.), Perspectives on Supply Chain Management and Logistics – Creating Competitive Organisations in The 21st Century, Dublin: Blackhall Publishers, 2007.